Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

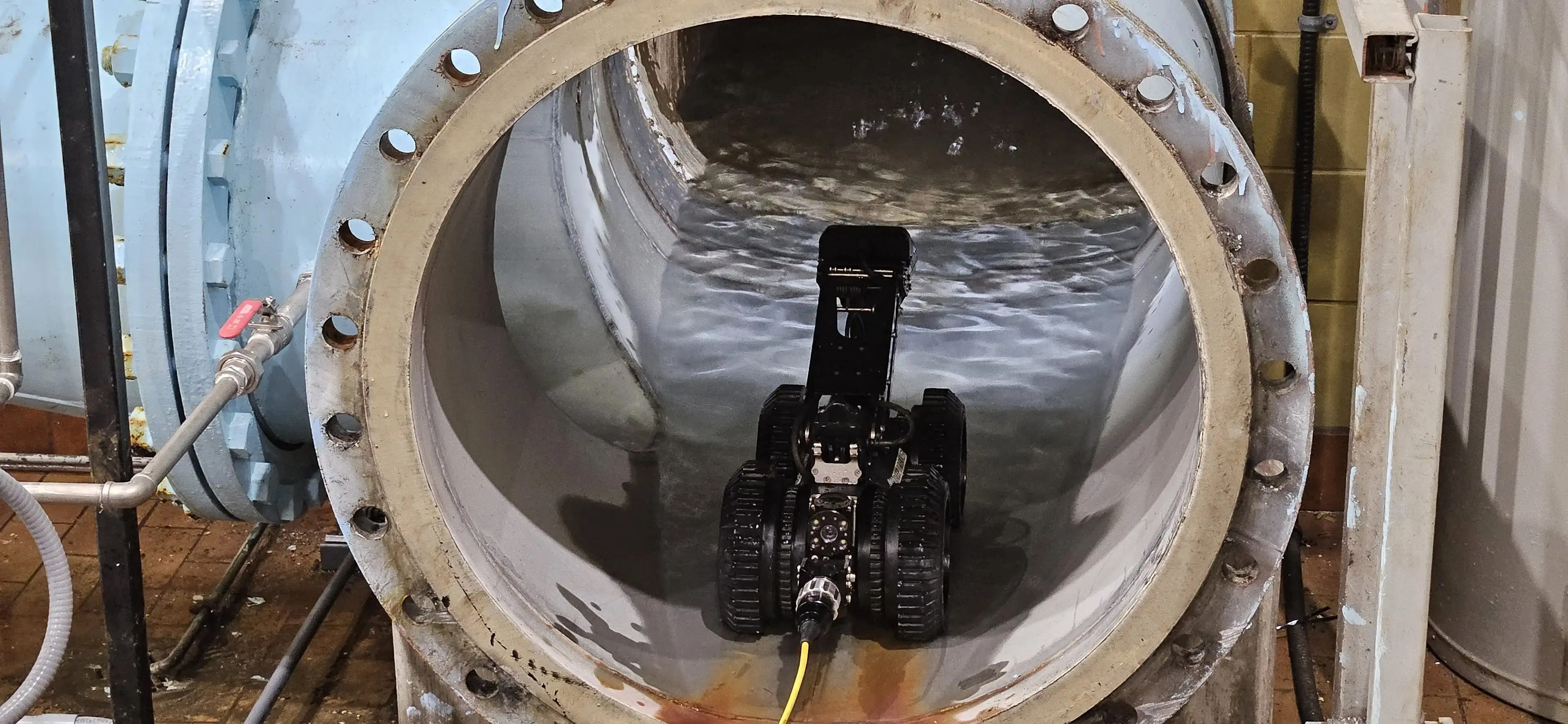

Pro Canada West Energy, a leader in oil and gas pipeline inspection, required a reliable method to verify welds and gasket integrity in pre-treated line pipe. The company turned to Deep Trekker’s Pipe Trekker A-200 pipe crawler, a robotic pipeline inspection camera system, to improve efficiency, reduce labor costs, and deliver higher-quality inspection data for its clients.

Pipeline construction projects often require internal pipeline inspection to verify weld integrity and ensure protective coatings remain intact. Pro Canada West’s projects involve pre-treated line pipe, a material similar to concrete but designed for durability.

As Darcy Singer, Major Projects Manager at Pro Canada West, explained:

“We use it for inspecting the welds in pipelines with pre-treated line pipe. So it's like concrete, but it's not concrete. We’re checking for gasket integrity, concrete’s integrity, that it hasn’t cracked, and it’s worked really well for us.”

Before adopting the Pipe Trekker A-200 crawler, the company relied on older pipeline inspection equipment “that didn’t work very well.”

The challenge was clear: traditional methods of pipeline weld inspection were labor-intensive, inconsistent, and produced lower-quality imaging results.

The Pipe Trekker A-200 pipe crawler is integrated into daily inspection routines across multiple major projects.

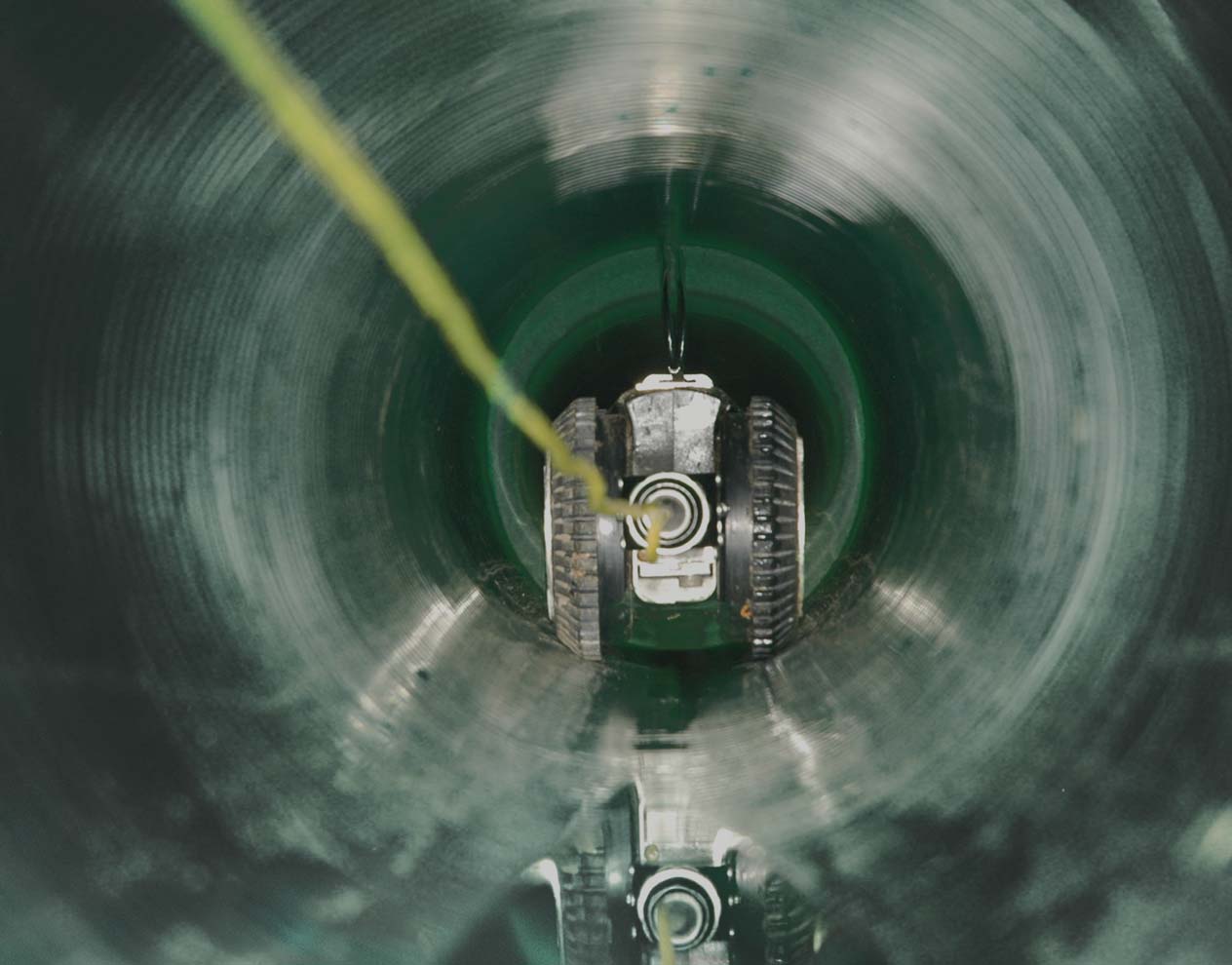

“Every day we’re inspecting about twenty-five to thirty welds. We also assemble around five joints together above ground, then carefully lower them, do the final weld, and run them back in about seventy-five to a hundred meters to check that weld. So really, every weld we do is inspected 100%, except for the last few finals that you can’t check.”

This pipeline inspection crawler is deployed immediately after welds are completed and coated, allowing the team to confirm structural integrity in real time.

Automation reduces repetitive strain on operators:

“I really like the auto return. Especially for how much we’re doing all the time, like going in and coming back a hundred meters right away, just to look at one weld.”

The A-200 delivered measurable improvements in inspection quality, speed, and ease-of-use.

Darcy described the differences compared to older pipeline inspection robots:

“Much better picture, better quality. Zoom features are way nicer.”

Higher resolution imaging and improved zoom made it easier to identify surface flaws, joint alignment, and weld quality in real time, reducing the chance of missed defects.

The ergonomic controller and onboard LED display also stood out:

“It’s really well-liked - nice to handle, easy to operate. I like the touch screen of the bigger remote, the LED tablet.”

Operators no longer needed to rely solely on external monitors or multiple cables. The integrated screen and simplified controls meant inspections could be carried out more efficiently in the field, even in constrained work sites.

Efficiency was another major benefit:

“Time savings. Before, we needed a few more people there reeling it in and stuff like that.”

With fewer personnel required to manage cabling and retrieval, the system reduced manpower needs. Tasks that previously required two or three technicians could now be completed with a single operator.

These improvements represent direct pipeline inspection cost savings, reducing both labor requirements and project timelines while improving the consistency of weld assessments.

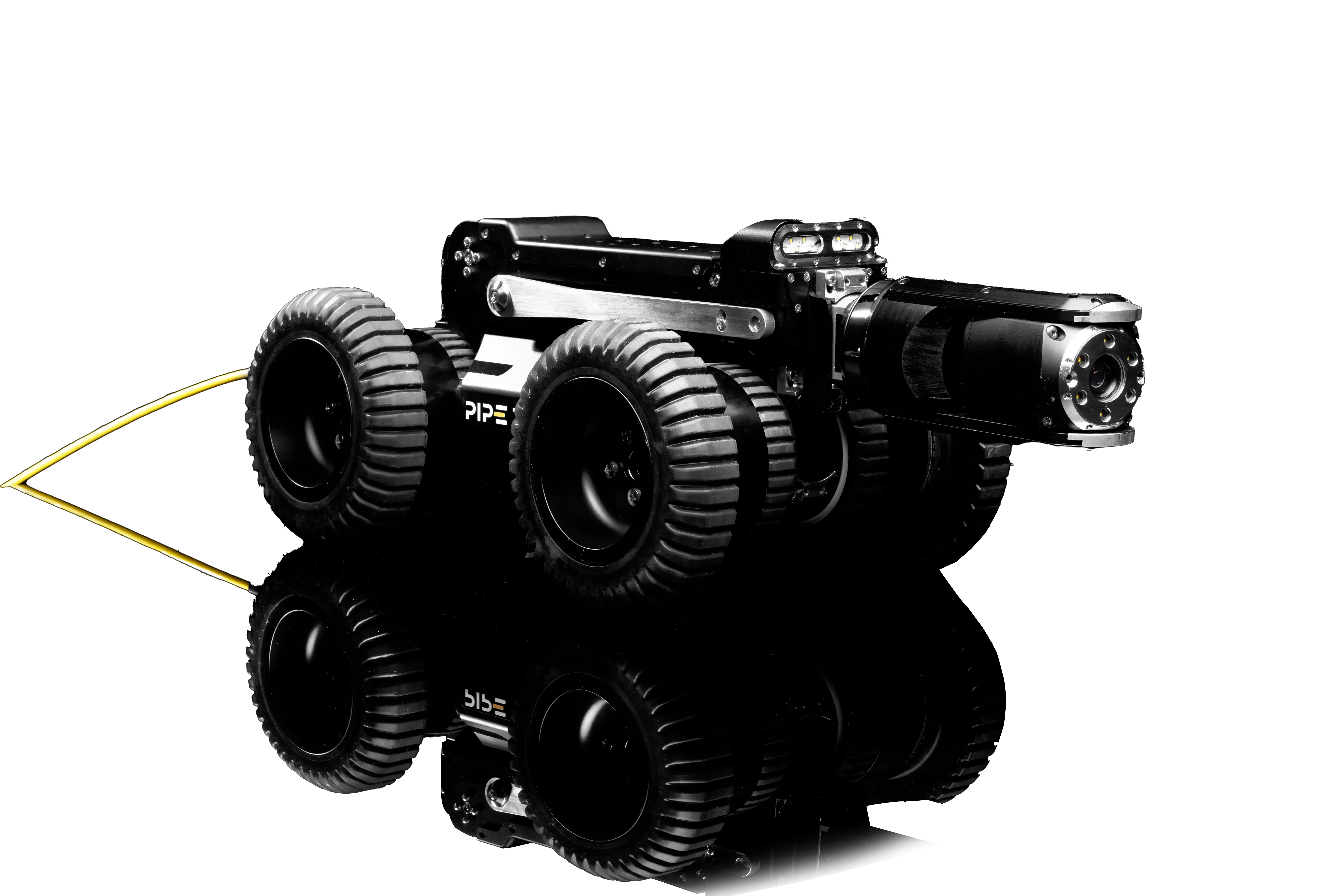

The A-200 pipeline inspection camera is designed for rugged field conditions, delivering:

Tether lengths supporting runs up to 200m.

High-resolution video and optical zoom for pipeline weld integrity checks.

Auto-return functionality for repetitive inspections.

Portable design for quick deployment in remote field conditions.

Pro Canada West has also deployed the crawler in brine pipeline inspection scenarios:

“We’ve used it several times for clients going into old existing pipe - just careful with it because we’re dealing with brine water baths. We haven’t submerged it yet, but I know it can. Especially brine, it’s not like water or sewage. It’s highly corrosive, hard on the electrical connection.”

St. Charles Parish Case Study: Modernizing Pipe Inspections with Pipe Trekker

Pro Canada West Energy integrated the Pipe Trekker A-200 pipeline inspection crawler into its operations to address challenges in pipeline weld inspections and gasket integrity verification.

By using the A-200, the company achieved better inspection quality, lower labor costs, and faster project turnaround.

As Darcy Singer concluded:

“Nice to handle, easy to operate, with much better picture and zoom features. It’s worked really well for us.”

Pan/tilt HD camera head

Tilt and roll sensor suite

Inflow and Infiltration Rehabilitation Methods - How To Fix Sewer Pipes

What is a Pipe Crawler and How Does it Work?

A pipe crawler is a robotic pipeline inspection device with cameras and lighting. It travels through pipelines on wheels or tracks, capturing live video of internal conditions for remote visual inspection (RVI).

Why Use a Pipe Crawler Instead of Manual Inspection?

Manual inspection often requires confined-space entry, which is hazardous and limited in scope. Pipe crawlers eliminate these risks, reduce crew requirements, and provide digital records of internal pipeline inspections.

How Far Can a Pipe Crawler Travel Inside a Pipeline?

The Pipe Trekker A-200 can travel up to 200 meters depending on tether length. In Pro Canada West’s workflow, runs typically extend 75–100 meters per weld.

Can Pipe Crawlers Be Used in Corrosive or Brine Pipelines?

Yes. As Darcy explained, the A-200 has been tested in pipelines exposed to brine. Operators must take care to protect electrical connections due to corrosion.

What Are the Cost Savings of Using a Pipe Crawler?

Robotic pipeline inspection reduces labor requirements, eliminates the need for scaffolding or confined-space entry, and speeds up weld verification. Pro Canada West directly reduced labor by eliminating extra personnel for reeling tasks.

How Do Pipe Crawlers Improve Weld Inspections?

Crawlers provide zoom-enabled, high-resolution video for pipeline weld integrity inspections, ensuring coatings and gaskets are intact. Pro Canada West uses the A-200 to ensure 100% of welds are inspected.

What Features Should You Look for in a Pipeline Inspection Crawler?

Based on operator feedback:

Auto-return functionality

High-quality video and zoom

Rugged design for corrosive conditions

Ergonomic, touch screen remote control

Our team consists of highly skilled professionals with extensive industry experience, dedicated to assisting you in integrating submersible robots into your operations seamlessly. Whether your project involves municipal pipeline and infrastructure inspections, wastewater system maintenance, salvage operations, confined space surveys, or other specialized applications, we are equipped to cater to your unique requirements and objectives effectively using our state-of-the-art robotic solutions.

When you're ready to secure your very own Pipe Trekker vehicle, feel free to contact us, and we'll be happy to provide you with a customized quote tailored precisely to your requirements. Incorporating Pipe Trekker crawlers into your operations ensures unmatched safety, efficiency, and success.

Need a Pipe Crawler for your next Inspection?