Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

Across any industry, staying on top of asset conditions is vital for safety, efficacy, and budget forecasting. Stormwater pipelines are no exception. Additionally, visual inspections of material storage and outdoor processing areas, as well as discharge areas and their surrounding environments are essential to a well functioning stormwater system. Over time, asset integrity begins to dwindle, and having consistent condition intel is the only way to minimize risks of contamination, flooding, blockages and collapsed pipes.

A stormwater inspection refers to a visual inspection of infrastructure dedicated to the management of rainwater. Stormwater systems are an integral part of modern societies, since rain water can not be naturally cycled through developed landscapes. These systems act to collect, manage, and maneuver rainwater for repurposing and redistribution away from communities. Consistent visual stormwater inspections are quickly becoming a standard for all NPDES stormwater discharge permits. Different levels of inspections should be conducted routinely, quarterly, and annually, with varying levels of focus and robustness.

Since routine inspections are not always required by permit laws, the frequency is up to the discretion of each individual organization. Routine inspections however, should be conducted to monitor the integrity of any equipment or infrastructure related to stormwater management. Higher risk settings should consider daily or weekly inspections, while more neutral environments may be able to operate with quarterly inspections. All inspections should be conducted by qualified personnel capable of identifying and reporting areas of concern.

Each quarter, as part of their SWPPP (Stormwater Pollution Prevention Plan) to maintain an NPDES Permit, organizations must visually inspect relevant infrastructure and sample all outflows. These samples must be taken under specific conditions. In order for the data to qualify, the sample must be taken within 30 minutes of a rain event after five days of dry conditions. The results are then documented and analyzed to determine effluent levels.

As per NPDES permit laws, annual inspections must provide comprehensive reports on the status of drains, pipes, materials which may have contacted stormwater, and sediment both onsite and offsite. Any identified issues such as spills or leaks must be reported with a control measure or repair schedule.

Depending on the size of the site location, stormwater systems can be immense. With the potential to affect millions of citizens or contaminate massive plots of land in the event of a system failure, detailed inspections are vital. When inspecting a stormwater system, there are a variety of potential issues that can be cause for concern.

- Cracks

- Leaks

- Offsets/Disjoints

- Ovality (the pipe squeezes into an oval shape)

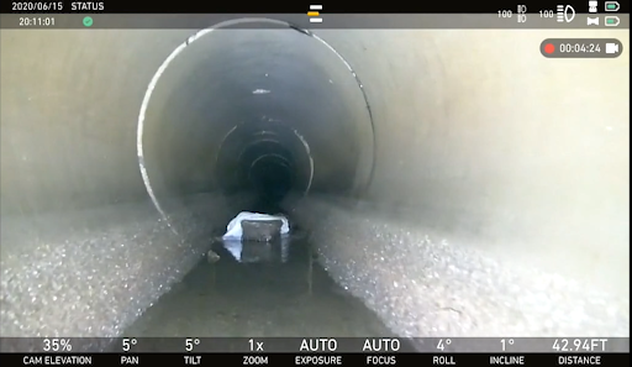

- Blockages in pipes/Sediment build-up (can be construction material, gravel, sand, mud, tree rooting)

- Obstacles such as cinder blocks, bikes, and other random objects are not uncommon in stormwater pipes since the access tends to be easier for civilians to access than sewers

- Corrosion

- Collapses

- Status of previous repairs

There are three core stages that treatment facilities go through to remove impurities from the wastewater:

- Primary treatment: Up to 60% of suspended solids are removed from the raw sewage as it passes through the primary settling tanks. Screening traps human waste and other solid objects while aeration helps push solids to the bottom for effective removal. However, only removing larger imperfections will still leave the treated wastewater with many toxic compounds.

- Secondary treatment: The goal of the secondary treatment is to remove the dissolved organic matter that remains after aeration and screening. This process adds microbes to the water to consume the organic matter and convert it to carbon dioxide, water and energy. This secondary treatment removes about 85% of the waste and most toxic chemicals from the water.

- Tertiary treatment: In tertiary treatment, the goal is to remove all remaining bacteria. Depending on the technology and the level of technical expertise available at the facility, this final stage of treatment may vary. Common tactics include a combination of ultraviolet radiation treatment, chlorine disinfection and additional microbe infusion. When done correctly, this stage of treatment can remove over 99% of all impurities from sewage.

Obstructions from external sources or sediment buildup can lead to a complete blockage of stormwater. With nowhere to direct flow, rainwater will build up and can result in substantial backups, floods, or uncontrolled runoff. These floods have the potential to cause millions of dollars of property damage or destroy surrounding habitats.

After the initial installation of a new stormwater system, inspections should be conducted after every rain event. This is to ensure that there are no flaws in the system that could compound if undetected. Once efficacy and safety is established, quarterly and annual inspections should be conducted to apply for/maintain NPDES stormwater discharge permits.

Regular inspections are more subjective based on a variety of circumstances and should be conducted as often as required for safe operation. To determine this, it is encouraged that risk assessment is conducted to deduce the potential safety hazards of the network. If the risk of widespread environmental or humanitarian impact is high, inspections should be performed more consistently as a preventative measure.

Another useful tool is to conduct an initial stormwater network inspection and introduce a grading system to plan and forecast maintenance schedules. By keeping a consistent report on the health status of the network, organizations can make informed decisions on inspection frequency. In some high-risk situations with aging infrastructure, it could even be recommended to conduct inspections daily or multiple times a day.

It is crucial to manage stormwater for several key reasons. With the proper tools, inspections are a non-invasive, low-risk preventative measure against issues in stormwater management. From the health of local waters and aquatic life to flood risk mitigation, the correct management of stormwater is imperative.

Improperly managed stormwater can reduce moisture replenishment in the soil and minimize groundwater recharge. Soil moisture is essential for vegetation, while loss of groundwater recharge can severely reduce stream baseflow - water necessary for aquatic life. By managing stormwater correctly, the hydrologic cycle can be maintained to ensure healthy plant and aquatic life.

Without adequate stormwater maintenance, the risk of flooding, especially in urban areas, is greatly increased. As water cannot be absorbed into the concrete that covers large swaths of towns and cities, the excess water from rain and thunderstorms must be managed to prevent loss of life and property damage by flooding.

While erosion is a normal part of stream behavior, excess stormwater can greatly increase the amount of erosion as abnormal amounts of water enter streams during storms. This extra water increases both the volume and rate at which water - and the sediment in the water - is delivered to streams. This extra water can increase erosion on stream banks and beds, damaging the natural form of these streams. The degradation of these streams can lead to a massive decline in plant and animal diversity. Proper stormwater management can effectively mitigate these risks.

While no future outcome is 100% predictable, inspection report data is a beneficial tool for educated predictions of budget allocation. By following a dedicated asset health grading system, facilities should be able to narrow down to the year when maintenance will be required. Having this information on hand lowers the risk for costly surprise repairs or large-scale collapses.

In order to conduct a proper inspection, a full visual and inside the length of the pipeline is required. Depending on the pipe dimensions and water levels, this can either be done manually or robotically using ROVs or Pipe Crawlers. Generally, in order for a pipe to be entered safely, the diameter must measure a minimum of 48” (122cm). In modern practice, many are opting for portable robotic solutions to streamline their visual inspections for safety, access a wider variety of pipes, and instantaneously run reports.

Pipe Crawlers are an extremely effective way to inspect dry or partially submerged stormwater pipes. All of Pipe Trekker’s Crawlers are fully submersible and have configurations that can center camera footage in pipes from 6” (15cm) to 36” (91cm) diameters. Utilizing an HD pan/tilt/zoom stormwater pipe inspection camera, similar to the one found in the A-200 provides the operator with extremely accurate visuals of imperfections along the pipeline.

NASSCO’s PACP certification provides municipalities and professionals with a straightforward, standardized way to document sewer conditions and defects. To perform NASSCO compliant PACP coded inspections with a pipe crawler, the camera head needs to be in the center of the pipe. In the case of a larger or partially submerged pipe, Pipe Trekker’s crawlers utilize robotic elevating arms to center the camera head above the water line. Stormwater pipes are often corrugated steel, HDPE, or concrete. Opting for pneumatic tires, tracks, or rubber wheels are ideal for traction on these materials. Tracks and pneumatic tires are adept at traveling through mud, sand, or for getting over debris.

For fully submerged large diameter pipes, ROVs are the most effective tool for visual inspections. Deep Trekker ROVs’ intuitive controls and tilt cameras make it incredibly easy to get crisp visuals of the entire pipeline. The powerful yet controlled thrusters allow for operators to pilot close to pipe walls and flooring without stirring up sediment.

A disadvantage to ROV inspections is that they are not PACP compatible. Since they do not follow the same pan/tilt/length count that a pipe crawler does, they are not technically NASSCO compliant. However, inspections can still be performed and to provide defect visuals and location estimates.

For partially submerged, large diameter (900mm/36”+) pipes, float can be a viable option. Floats can provide multi sensor capability and can travel long distances, but generally need significant flow to operate. For extremely large tunnels that are dry, manned entry is still a reasonable option. However, deploying a crawler is the safest alternative.

Visual inspections provide integral information to municipalities or organizations about the status of their storm and sewer infrastructure. Using tested and validated reporting programs ensure that teams are provided a convenient import and export using the NASSCO file.

There are several NASSCO certified software options that are used to document PACP inspections. By consistently developing and archiving verified asset reports, pipes can be tracked and monitored with accuracy over extended periods. Pipe Trekker is proud to offer straightforward WinCan and POSM software compatibility. Integration is also available with GraniteNet, ITPipes,and CTSpec among others.

Want to know which crawler is best for your application?

Owning equipment in lieu of hiring out inspection contractors comes with a multitude of benefits. Hiring external inspectors for routine, quarterly, and annual inspections add up to significant sunk costs over the long run. By purchasing a crawler inspection system from Pipe Trekker, municipalities are empowered to conduct internal inspections. With intuitive controls, simple modular adjustments, and seamless integration in certified reporting, virtually any staff member can be trained to operate a crawler.

Having the ability to conduct inspections internally also provides exceptional time savings. Traditionally, if a problem is reported, a city will be required to coordinate timelines with an external service company to inspect. With a crawler, internal employees can load a Pipe Trekker crawler into virtually any vehicle and deploy in minutes. This limits downtime and allows for immediate responses to reported incidents.

Beyond dollar and time savings, purchasing and implementing a crawler or ROV for stormwater inspections increases the safety of employees. Keeping a remote vehicle on standby ensures that employees have a safe alternative to manned entry. This also allows for a proactive method to quickly address potentially dangerous situations and avoid major defects such as backups and collapses.

Implementing a Pipe Trekker crawler or Deep Trekker ROV for stormwater inspections empowers operators to conduct inspections safer and easier than ever before. From 2011 - 2018, 61 fatalities were reported on the job inside a manhole, sewer system, or storm drain. With the use of remote inspection vehicles, operators never have to enter a confined space.

A comprehensive lineup of fully submersible robots allows for in-depth inspections of a variety of pipe sizes and situations. With carbide grit, pneumatic, rubber, or track wheel options available, Pipe Trekker’s crawlers can be adjusted for countless missions. The pan/tilt/zoom full HD camera provides operators crystal clear recordable video with near-zero latency for smooth operation.

New in 2022, Pipe Trekker’s A-200 offers the convenience of hybrid power. Inspection teams have the option of utilizing the on-board batteries for a completely portable system, or deliver endless topside power via a powered reel for extended drain and pipe camera inspections. If opting for battery power, systems condense down into two wheeled Pelican carrying cases for easy transport in any vehicle. From a full charge, Pipe Trekker’s crawlers run for up to eight hours to ensure a full day’s work.

Contact a Crawler Specialist for more Information

The town of Renfrew is a small municipality, with a storm and sanitary system including 89 km (55 miles) of pipe. In 2005, Renfrew hired a CCTV service company to inspect 75% of their system, totaling $400,000 to complete. The town used to call on a contractor 10 - 12 times a year to provide CCTV services.

Renfrew understood that CCTV camera inspections of storm water pipes ensure the integrity of the system, and minimize risks of contamination, flooding, blockages and collapsed pipes, although the high cost of inspections limited their abilities to do so. Their mission was to reinvent this process in order to minimize these sunk costs for continuous inspections while maintaining employee safety.

A DT340 Pipe Crawler was a perfect solution for Renfrew’s high inspection costs. At the time, a DT340 system cost USD$13,000 to purchase, and gave their internal staff the ability to effectively inspect pipelines 8 - 36” in diameter.

Internal, on-board batteries mean that no generators or topside power sources are required. Traditionally, CCTV inspection systems require a dedicated truck for all of the components including a tether, winch, and power source. The Deep Trekker DT340 packs down into two carrying cases and can be set up and deployed in less than a minute.

See the full story here.

Brantford is a city of approximately 100,000 people with a variety of storm and sanitary pipes that the city's Environmental Services team is responsible for. Some challenges the team has faced in the past have been waiting on contractors for emergency inspections and getting a visual for their cutters performing work on rooted pipes.

The DT340X Package provided a simple yet sophisticated system for quick visual inspections. John Longo, Supervisor of the Water Distribution & Wastewater Collections Division, originally saw the DT340 at the WWETT show in Indianapolis earlier that year: "I really liked the versatility of being able to send one guy in a truck to figure out exactly what we need to do. No waiting on expensive emergency services or going in blind with our cutters, it just makes a lot of sense for us”.

Opting for the X package, Brantford was able to take on larger diameter pipes thanks to the elevating arm and larger wheel configurations. The modular arm arm allows the operator to remotely raise the camera via the handheld controller. This, along with the included larger wheel sets allow the crawler to position the storm drain camera in the center of 36” pipes or above the water line in partially submerged pipes. Centered video also allows for expansion into using the crawler for PACP coded reports.

See the full story here.

As always our team of experts is available to answer any questions you may have. When you’re ready to take the next step and get a pipe crawler of your own, reach out for your customized quote.