Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

Trenchless sewer rehabilitation refers to the repair, replacement, or upgrade of sewer pipes. The term ‘trenchless’ means that workers are using technologies to perform rehabilitation methods without any excavation. These methods include pipe relining, curing, sealing, or grouting, as well as manhole replacement or relocation, and other spot repairs. One of the most common symptoms of sewer pipe malfunction is inflow and infiltration.

Traditionally, sewer pipe rehabilitation often required digging trenches to reach the pipes, which can be incredibly costly, time-consuming, and destructive. With modern technological advances, we can now approach Infiltration and Inflow (I&I) issues more efficiently and less invasively by using modern trenchless sewer line repair methods.

I&I (Inflow and Infiltration) is when groundwater (infiltration) and stormwater (inflow) enters the wastewater causing overflow, floods, contamination, and damage to the sewer lines. In many cases, I&I accounts for up to 45% of the annual flow to treatment plants. This, of course, can result in significant increases in cost for wastewater treatment plants and damage to sewer systems due to overflow that is beyond what the sewer pipes were built to manage.

Groundwater can breach sewer pipes through cracks, leaking pipe joints, faulty manhole covers, and connection failures along the pipeline. This is known as infiltration. The severity of sewer infiltration can be dependent on seasonal weather, such as heavy storms during wet seasons that increase groundwater levels and cause overflow in volume.

Cracks and leaks in a pipeline are generally caused by age and deterioration, wear and tear, tree root infiltration, loose pipe joints, ground movement from temperature changes, material breakdown, debris inside the pipe, improper installation, and damage caused by natural weather flow. Broken pipes can result in excess water levels entering sewer systems and wastewater treatment plants, which can become incredibly costly if neglected or overlooked.

Inflow happens when stormwater enters into sewer systems through yard and storm drains, malfunctioning manhole covers, roof leaders, basement sump pumps, indirect connections to storm sewer pipes, and catch basins.

This can happen due to heavy rainfall, and snowfall (or snow melting), resulting in overflow and pooling of water that can cause severe and costly damage if access points are left untreated.

The main difference between inflow and infiltration lies in where the excess water comes from. To put it simply, inflow comes from rainwater (or stormwater) entering the sewer system, whereas infiltration comes from groundwater entering the pipes. Groundwater levels are typically affected by seasonal variations, while stormwater levels generally occur from heavy storm events or snow melt.

There are many methods for inspecting and identifying I&I to collect vital information needed to expose where issues are happening and isolate potential vulnerabilities and problem areas in sewer lines. Here are some effective ways to inspect sewer pipes for I&I:

Sewer flow monitoring is the process of analyzing and measuring the water pressure of sanitary sewer systems over time and comparing it to the estimated baseline of the hydraulic characteristics of the sewer pipes.

Once data has been collected, it can be used to prioritize areas for further inspection to identify I&I origins and prevent damage from escalating into serious and expensive problems. This can be accomplished by installing sewer flow monitoring equipment like flow meters (and sensors) and monitoring both dry days and wet weather days, then using the data to calculate the average daily flow and measure how much I&I is in the collection systems.

Recommended Article: How Deep Trekker Crawlers Benefit Remote Operators

Manholes are access points into the sewer, used to conduct maintenance. Because of this, it also means they are access points for water to leak in. This happens when a manhole ages and deteriorates, becoming a crucial source of I&I.

Regular inspections are vital for revealing any issues and proactively resolving them before they become larger and more costly issues to deal with.

Smoke testing is a practical method of inspection, which consists of setting up a smoke blower to pump non-toxic, simulated smoke into the sewer lines to reveal I&I points of entry.

This method is typically used in commercial settings that have flat roof buildings, parking lots, and other large drainage zones. It can also be used in residential locations, but is generally limited to right-of-way areas rather than directly on residential properties.

Dye testing is the method of using water mixed with a non-toxic dye to identify leaks in the infrastructure of sewer lines. This method can also be used in conjunction with smoke testing to confirm the results found through the smoke testing inspections.

To evaluate the sewer systems, coloured water is pumped into the groundwater and stormwater, and will appear in the sewer lines where there are leaks. If no coloured water enters the sewer pipes, then they are likely in good condition and do not require repair.

When inspecting sewer pipes with flow levels where equipment could be submerged, or semi-submerged, and visibility is potentially low, or obstructed, sonar is an excellent option for inspection.

Sonar uses sensors to detect sound wave variations or vibrations to identify leaks or defects. This method is ideal for capturing accurate data in submerged pipelines, real-time 2D profiles of the pipe walls, as well as measuring debris and sediment depth within the sewer pipes.

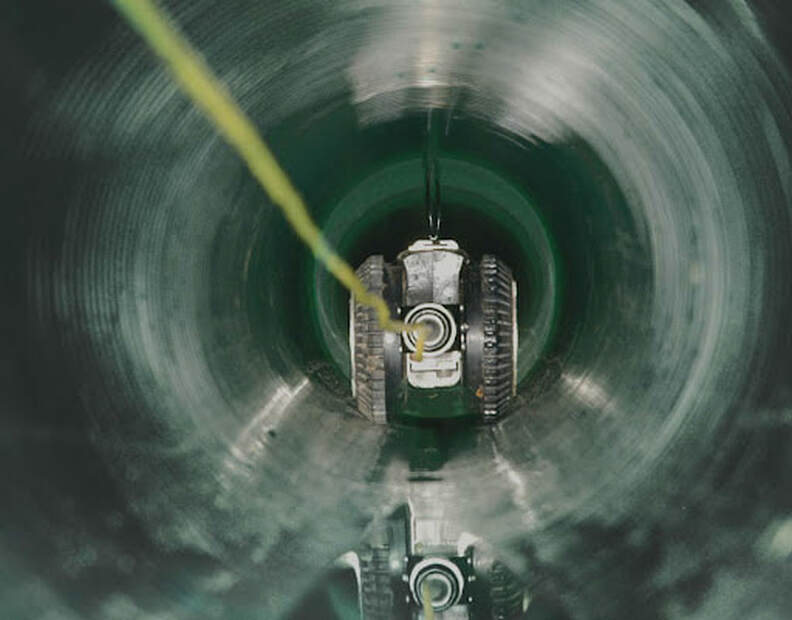

The best way to get actual eyes inside the sewer pipes is through CCTV inspections. CCTV inspections consist of a small, non-invasive camera that is sent into a sewer pipe system to send real-time visuals to the operator and identify leaks and defects as it travels down the length of the pipe.

This method is great for using in conjunction with sonar inspections, especially when the pipe has flow levels and limited visibility.

One of the largest contributors of inflow and infiltration into sewer systems is residential sump pumps and foundation drain lines that are improperly connected to the nearby sanitary sewer laterals.

During a heavy rainfall event, a single sump pump can send almost 7,000 gallons into the wastewater systems, which is approximately the same amount as the average daily flow of 18 residential homes.

These methods, as mentioned, can be used in conjunction with each other and serve as excellent preventive measures that can save municipalities and communities thousands of dollars. For example:

“A single joint leak in a pipe or manhole can generate 7,200 gallons of water per day – or an annual cost of $5,000-13,000 after being treated. Addressing even the smallest leaks in your system can generate significant savings.” – Spencer Cossalter, Water Resources Project Design Leader

Recommended Article: Pipe Inspection Robots Everything You Need to Know

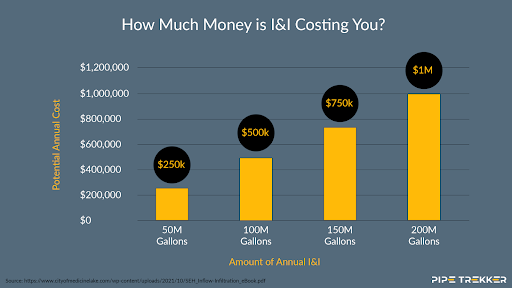

Wastewater collection systems can be damaged when they are forced to support more water flow than they were designed to manage. Stormwater and groundwater mixing with sewage can mean dramatically increased costs for a wastewater treatment plant, with estimates of up to 50% of flow being inflow and infiltration, especially in aging infrastructures. Annual volumes can reach as high as 200 million gallons and can cost up to $1.2 million per year to transport and treat.

If strategies to prevent and repair infiltration and inflow are not implemented, it can cause:

- Sewer backups

- System overflows

- Risks to health

- Damage to the environment

- Increased operational costs for treatment plants

Not only can infiltration and inflow be costly if not proactively dealt with, but can also dramatically reduce the capacity of treatment plants, contaminate ground and surface water, as well as nearby bodies of water, cause pipe structure failures, and land subsidence due to underground soil erosion, to name a few issues.

This is why sewer pipe inspections are so vital to maintaining the health of wastewater systems. Thanks to modern innovations and technologies, these inspections can be done in a variety of ways, and most often, do not require digging trenches any more.

Let us help you find the right crawler for your next pipe inspection.

Traditional sewer pipe repair techniques can be highly invasive, destructive, expensive, and time-consuming. Having to dig trenches involves heavy excavation equipment, mountains of dirt, the closing off of roads, potentially months of work, and the unfortunate destruction of your beautiful landscaping efforts and the associated cost of restoration.

Unlike traditional methods, trenchless sewer pipe rehabilitation doesn’t require digging into the ground, making it much more efficient, cost-effective, less invasive and destructive, requires dramatically less time to complete, and, using modern materials, can last for decades. For example, High-Density Polyethylene (HDPE) is a plastic resin that has been in use since the 1950s and has a life span of 50 to 100 years.

There are four common types of trenchless sewer line repair:

One of the most popular trenchless pipe rehabilitation methods is using Cured-in-Place-Pipe (CIPP) lining to repair sewer pipes for lateral sewers, storm lines, and water mains. The CIPP process eliminates the need to excavate broken pipes by using a textile liner tube and a liquid resin to create a pipe within a pipe with minimal change to the diameter of the original pipe.

The flexible, resin-saturated liner, made of polyester, reinforced fiberglass, or a hybrid mix of materials is inserted into the pipe using a winch or several other inverted methods, such as air pressure. Once in place, the liner is inflated and the resin is activated using hot water, steam, or ultra-violet (UV) light, allowing it to cure and harden, creating a smooth, corrosion-resistant new pipe wall.

This method can be used on a variety of pipes, including non-circular pipes, pipes with multiple bends, offsets, or misaligned joints, and can last for up to 100 years.

Another cost-effective sewer pipe rehabilitation method is slip lining. Slip lining is performed by either pushing or pulling a smaller, new pipe into an older sewer pipe and then grouting the annular space between the two pipes to prevent leaks and provide structural support.

This method is generally limited to straight sewer lines since the rigidity of the liners and grout makes it difficult to use in pipes that have large obstructions or sharp bends. The most common material used for the liners is high-density polyethylene (HDPE and PE) and polyvinyl chloride (PVC).

Pipe bursting is a trenchless Sewer line replacement method that involves fracturing the existing broken pipe and replacing it with a new high-density polyethylene (HDPE) pipe, and pushing the fragmented pieces into the surrounding soil. This method does not require the use of chemicals or other contaminants and is incredibly sustainable due to the long life span of environmentally safe HDPE pipes.

Pipe bursting is performed by pulling a special type of drill called a bursting head through the existing pipe, and fracturing it while pulling the new HDPE pipe into place behind it. This method can be used with most pipe materials, other than HDPE sewer pipes, works on a wide range of internal pipe diameters, can be used at pull lengths of over 300m (1,000ft), and allows for an increase in the diameter of the pipe to improve flow.

Point and spot repair refers to a more localized pipe rehabilitation method, compared to the other end-to-end options, used for smaller cracks and flaws when the damage to the sewer pipes is not widespread. This can include grouting, cured-in-place-pipe (CIPP), or mechanical spot repair. This method is generally faster, more cost-effective, and less disruptive than end-to-end pipe rehabilitation solutions since it only focuses on smaller, more localized defects, rather than repairing longer segments of the pipeline.

Recommended Article: NASSCO PACP Certification and Inspection 101

Once the exact location of the damage has been pinpointed, the repair can be performed using grout, a form of liquid concrete used between the lining and the pipe to make a seal, CIPP (which was discussed above), or mechanical spot repair, which inserts a stainless steel sleeve surrounded by a foam gasket positioned over the damaged area, guided using a CCTV camera. The gasket, impregnated with grout fills the space around the core until the foaming grout fills the annular space, and penetrates the cracks in the pipe.

Since pipe bursting replaces the existing sewer pipe without the need to remove or dispose of the broken pipe, this method is incredibly cost-effective and dramatically reduces the required project time to complete, making it an excellent option for trenchless sewer line replacement.

When dealing with infiltration and inflow issues, there are plenty of options available to resolve the situation, and while trenchless sewer line rehabilitation is generally a preferred method, it is not always possible.

Recommended Article: Improving Municipality Worker Safety With Pipe Crawlers

Traditional methods for sewer line replacement are sometimes necessary, requiring heavy excavation equipment, longer time to complete the project, and any costs associated with repairing and restoring landscaping or roads. Each method has its pros and cons, and there are many variables to consider beyond cost and time constraints when deciding which method is best for the project.

When the sewer system does not run underneath a road or building, digging out the pipe might be the easiest option to complete the job, since you can inspect the pipe after it is replaced to ensure the installation was done correctly, as well as being able to easily confirm that the new pipe is in the proper position and will not fail.

However, if the sewer lines do run underneath a road or building, you will need to keep in mind that everything will need to be replaced, including landscaping and the building, which, of course, can be extremely costly and time-consuming.

Trenchless sewer line rehabilitation has many options available, and many benefits over traditional methods. Of course, as with any project, there are always pros and cons to the methods you chose to employ, and many factors must be considered when deciding which method best suits the situation - so it’s a good idea to explore those pros and cons to find the best solution.

When you’re faced with Infiltration and Inflow issues and you’re looking for a no-dig, trenchless solution, Pipe Trekker crawlers are the perfect tool for helping you perform the job quickly, efficiently, and in a budget-friendly manner.

To give you an idea of how financially beneficial using a crawler can be, check out this case study on the town of Renfrew, where they were able to save nearly $400,000 by using a Pipe Trekker crawler to inspect their storm and sanitary system including 89 km (55 miles) of pipe.

Pipe Trekker crawlers are specifically designed to meet the challenges of inspecting municipal sewer pipelines. Our units are battery-operated and fit into a case or two, allowing you to be truly portable, come equipped with high-quality pan/tilt/zoom HD cameras and elevation arms, giving you eyes in areas that are too confined or dangerous for operators to enter, and built to be rugged and fully submersible up to 50 meters (164 feet), making them ideal for almost any environment.

With a Pipe Trekker crawler, you can easily and quickly report on:

- Cracks, fractures, holes, pipe defects

- Leaks and infiltration

- Blockages and other obstacles

- Broken or collapsed pipes

Right out of the box, you have a variety of proven options to solve many challenges you might face, with accessories like tracks, wheel options for crawling different types of pipe material, active freewheel mode to make unit retrieval a breeze, WINCAN integration, and an elevated camera head, to name a few.

Whatever your project is, we have a customizable solution for you! Want more information on how Pipe Trekker crawlers can make I&I inspections easier, safer, and more affordable for you and your team? Our team of industry experts are available to answer any questions you may have about our pipe crawlers, reach out today!